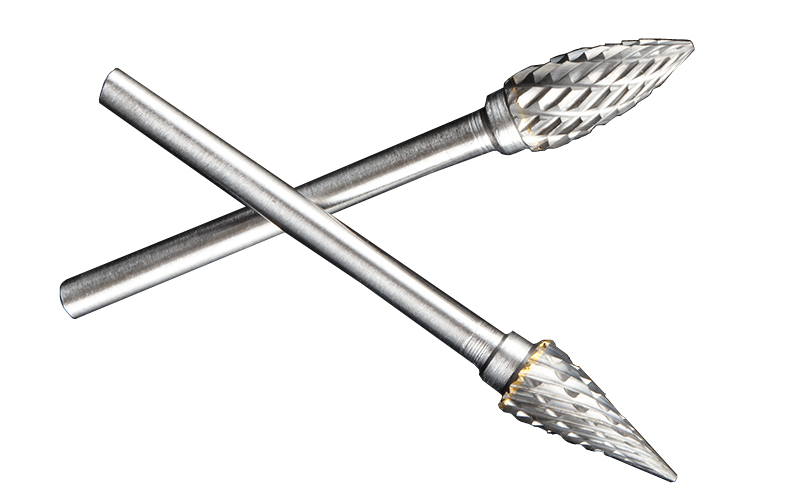

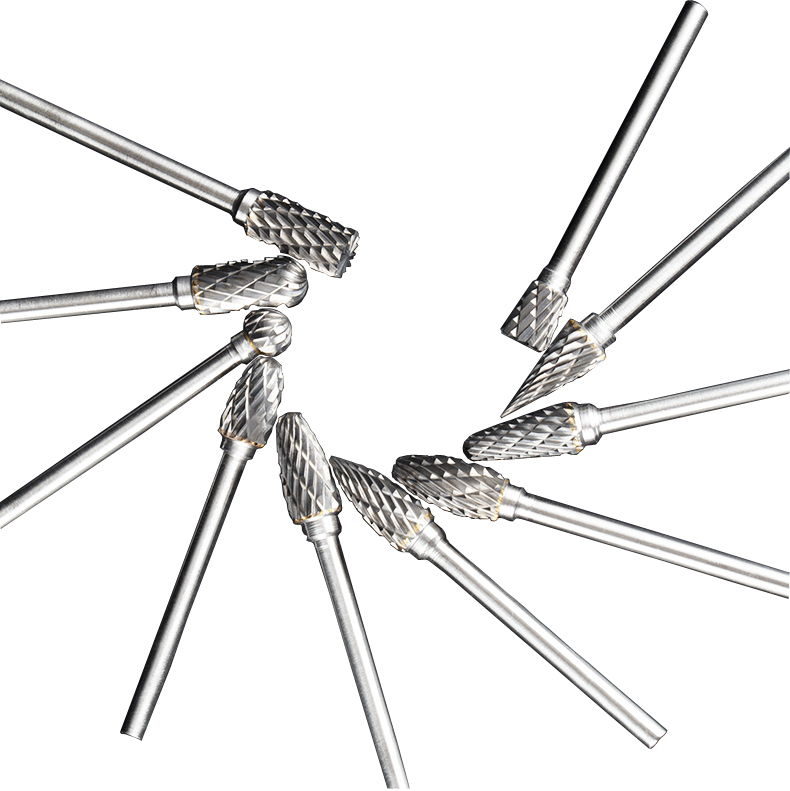

Tooth shape:Double cut or as request

Head material:Tungsten carbide

Shank material:Steel

Type avaible:A.B.C.D.E.F.G.H.J.K.L.M.N.S.X

We manufacture and specialize in tungsten carbide burr die grinder bits, all made right here in China.

What is Tungsten Carbide Burr?

Tungsten carbide burr, often referred to as rotary files or die grinder bits are used for cutting, shaping, and grinding, and for the removal of sharp edges, burrs and excess material (deburring).

Helpful notes: For drilling holes in hard metals you would need to use carbide micro drills or carbide straight shank drills. For cutting slots, routing, profiling, contouring, counter-boring, and reaming you would use a a carbide end mill, carbide slot drill or a carbide router. For cutting and shaping stone or glass you would use a Diamond Burr.

The Advantages of Tungsten Carbide Burrs?

Long life

Use for long production runs

High stock removal

Ideal for using on many hard and tough materials

Ideal for Deburring, finishing, carving, shaping and smoothing welds, moulds, dies and forgings

Tungsten Carbide Burrs are Harder than HSS Burrs.

Good quality Carbide Burrs are machine ground from a specially chosen grade of carbide. Due to the extreme hardness of the Tungsten Carbide they can be used on much more demanding jobs than HSS (High Speed Steel).

Carbide Burrs also perform better at higher temperatures than HSS so you can run them hotter, for longer.

HSS burrs will start to soften at higher temperatures so carbide is always a better choice for long term performance.

Head diameter:

Metric Units:3,6,8,10,12,16,19,22,25.

Imperial Units:1/8’,5/32’,3/16’ ,1/4’,5/16’,3/8’,7/16’,1/2’,5/8’,3/4’,7/8’,1’.

Shank Diameter:3mm or 6mm or 1/4’or 1/8’ or long shank 150mm,also can be designed as customer’s request..

Application:

Double cut carbide burrs tend to be used on ferrous and non ferrous metals, aluminium, soft steel and also for all non-metal materials such as plastics and wood. They have more cutting edges and will remove material faster. These are the most popular cut and will see you through most applications.

Double cut are sometimes referred to as Diamond Cut or Cross Cut (2 flutes cut across each other) . They will leave a smoother finish than single cut due to producing smaller chips as they cut away the material. Use for medium-light stock removal, deburring, finishing and cleaning.

Medium- light removal of material

Deburring

Fine finishing

Cleaning

Smooth finish

Creates small chips

What Speed or RPM should you use your Tungsten Carbide Burrs?

The speed at which you use your carbide burr in your rotary tool or die grinder will depend on the material you're using it on and the contour being produced, but it's safe to say you do not need to exceed speeds of 35,000 RPM. The table below shows some approximate speeds.

Helpful note: If the burs are chipping easily this could be due to the speed being too slow. However, it's ideal to start the cutting slow, increasing the speed as you go along. High speeds will prevent clogging in the flutes of your burrs.

Diameter of Burr RPM

3mm or 1/8" 17,000 - 26,000

6mm or 1/4" 11,000 - 16,500

12mm or 1/2" 8,000 - 12,000

16mm or 5/8" 7,650 - 11,500

E-mail: sales@ztcarbide.com

Add: No.1 of Longxin international building, No.255 of Tongxia Road,Shi Feng District, Zhuzhou Hunan Province,China

We chat